Windmills are powered by air.

Turbo-jets force hot gases onto blades to produce spin.

|

STOCKDALE MILL

|

What is a turbine?

A turbine is a wheel with blades that is turned by air, steam, or water.

Wind turbines:

| A child's pinwheel is a turbine. Windmills are powered by air. Turbo-jets force hot gases onto blades to produce spin. |

|

|

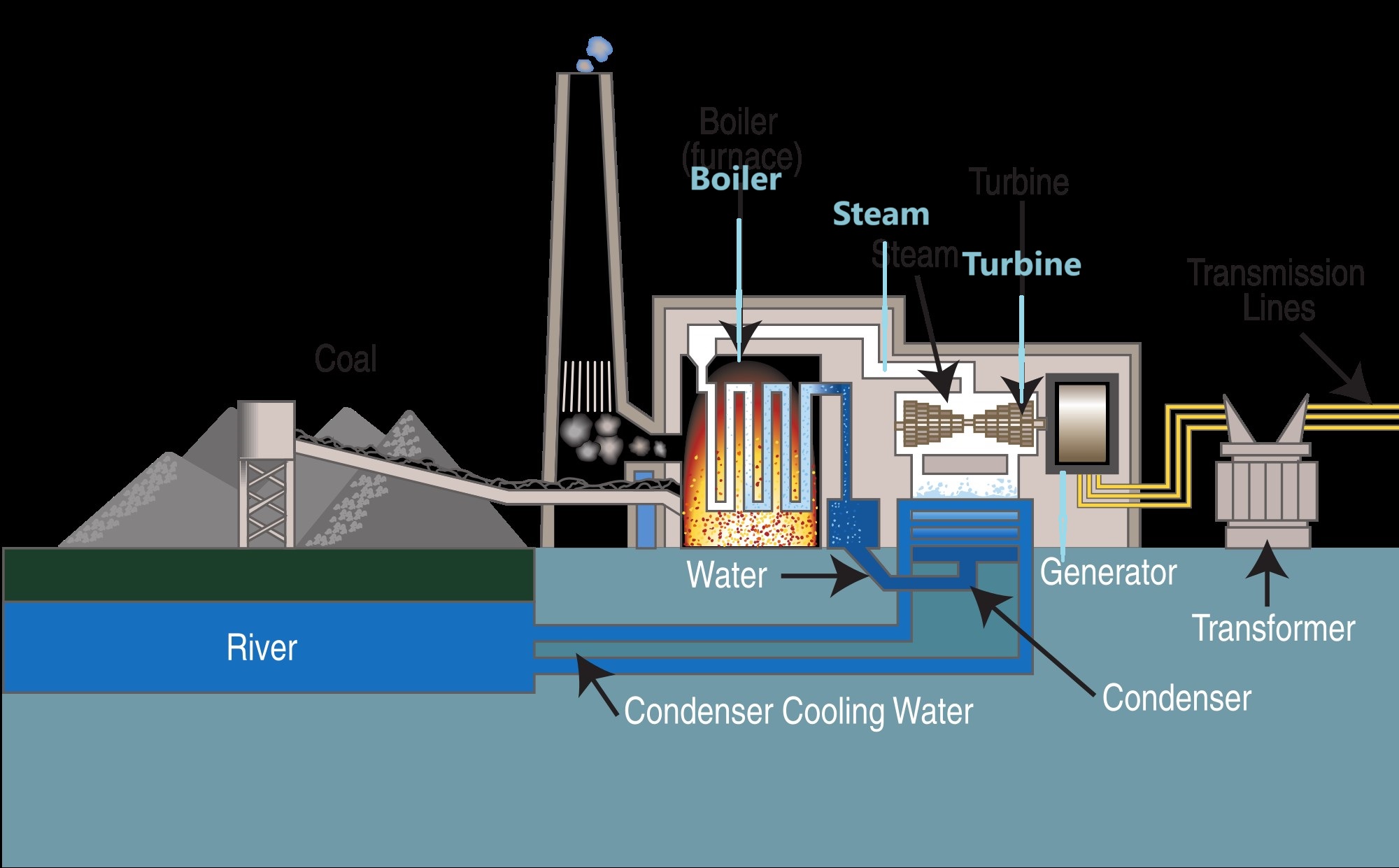

Steam turbines:

Coal, oil, gas, or nuclear fission create heat to turn water into steam. The

steam is forced though a nozzel (jet) directed towards blades on a shaft creating

spin. The spinning shaft powers a dynamo to generate electricity.

Steam turbines are used for many other applications including power for ships

ships.

Water turbines:

Water wheels were known to ancient cultures. Water turbines were first developed

in the late 1700's to produce more efficient power.

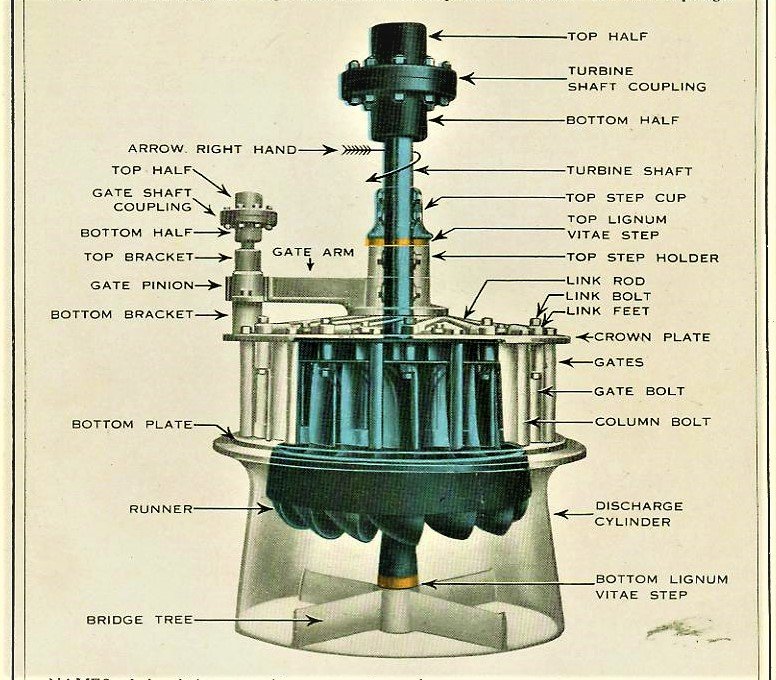

A dam on a stream creates a reservoir (pond or lake) of water. The Stockdale Dam is approximately 6feet high. Water is diverted from the reservoir to the mill turbines by a race (channel). The Stockdale Mill race is concrete, it channels water behind the parappet at the north end of the dam. A flume (or penstock) is where the water accesses the turbine. A grate seperates the race from the flume to catch debris (trash, limbs, ice) from entering the flume. The Stockdale Mill penstock is a concrete lined sub-basement under the mill housing the 3 turbines. Gates are used to control the flow of water to the turbines to regulate power. In the Leffel turbines at the Stockdale Mill, the gates are a part of the housing surrounding each turbine. The Stockdale Mill turbines are completely submersed in the water of the flume, only the central shaft of each turbine is visible reaching up to the mill. The operator operates a control wheel on the main floor to adjust the gates to produce the proper power requirements. As the gates open, water flows to the blades of the turbine. The weight of the water (water weighs 8 pounds gallon / 62 pounds per cubic foot) propels the blades (or runners), causing them to rotaten. A vertical shaft is connected by gears to the line shafts in the basement of the Stockdale Mill. The line shafts distribute the power to the milling equipment.

The Stockdale Mill always used water power. It is one of the very few remaining mills that was never converted to steam power or electricity.

|

|

|

||

| Adjusting gates on Stockdale Mill Leffel turbine | Stockdale Mill turbine exposed during restoration | Stockdale Mill turbine (on side) being lowered back into place after rebuilding |

The amount of power is determined by the size of the turbine, the volume of water available (flow) and by the 'head' (or 'fall'). The head is the difference in height of the water level at the top of the dam (flume level) and the water level at the bottom of the dam (discharge level). The Eel river has ample flow to power the 3 turbines. Very rarely would the power be reduced due to the lowering of the river level above the dam. Durnig flooding, the river level below the dam rises and the head diminishes. At high flood level no power can be produced. Leaves or ice collecting in the grates of the race can reduce the flow of water reaching the flume, so the grates have to be kept free.

|

|

| Eel River flow during the first 6 months of 2002 at North Manchester (cu. ft. / sec.) | Eel River flow during the first 6 months at Logansport (cu. ft. / sec.) |

| Click for today's river level at North Manchester on the web. | Click for today's river level at Logansport on the web. |

Note: A flow of 600 cu. ft. / sec. is about 37,200 pounds of water each

second.

Note: Eel River is 732' above sea level at North Manchester and 621'

at Logansport for a fall of 111' over the distance.

Large hydro-electric power stations (Hoover Dam) work on the same principal with a generator attached to the top of the turbine.